Future Events:

April 28th – Tuesday – IU Health Fort Wayne: Job Site Tour

Lunch, Presentation & Job Site Tour – Multiple AIA CEUs

Location: IU Health Fort Wayne Job Site (9600 Lower Huntington Rd Fort Wayne, IN 46809)

Time: 11:00-2:00PM

Event Co-Hosts: BEC Indiana, AIA Fort Wayne & Pepper Construction

MORE DETAILS & REGISTRATION LINK sent out via our BEC IN Announcements – Subscribe Here!

May 12th – Tuesday – Dissimilar Materials & Compatibility

Breakfast & Presentation – AIA CEU

Location: Grandview Conference Room @ American Structurepoint

Time: 8:00-10:00AM

Presenter: Marcy Tyler – Director of Building Science – Tremco CPG

MORE DETAILS & REGISTRATION LINK sent out via our BEC IN Announcements – Subscribe Here!

June 9th – Tuesday – Flashing & Moisture Control Best Practices: Reviewing Masonry Wall Assemblies

Breakfast & Presentation – AIA CEU

Location: Grandview Conference Room @ American Structurepoint

Time: 8:00-10:00AM

Presenter: Joe Alberts – Dir Industry Development & Technical Services – International Masonry Institute

MORE DETAILS & REGISTRATION LINK sent out via our BEC IN Announcements – Subscribe Here!

August 20th – Thursday – A Little Light Reading: Contractor’s Guide to Specifications

Dinner & Presentation – AIA CEU

Location: Blind Owl Brewery (5014 E 62nd St Indianapolis, IN 46220)

Time: 5:30-8:00PM

Event Co-Hosts: CSI Indianapolis & BEC Indiana

Presenter: Amy Baker AIA, CSI, CDT, SCIP – Specification Consultant & Architect – Amy Baker Architect

MORE DETAILS & REGISTRATION LINK sent out via our BEC IN Announcements – Subscribe Here!

PREVIOUS EVENTS

Event: Tuesday Feb 10th, 2026

Things that Spray – Performance, Placement & Building Science Behind Spray-Applied Enclosure Materials

Receive (2) AIA LUs via LIVE DEMONSTRATIONS

Event Details:

DATE: Tuesday, February 10th, 2026

LOCATION: Pepper Construction – 1850 W. 15th Street, Indianapolis, IN 46202

Click Address for Directions 1850 W. 15th Street, Indianapolis, IN 46202

SCHEDULE & EVENT NOTES:

- 11:00-11:30am Check-in, Networking & Box Lunch

- 11:30-12:00pm Welcome, Introductions & Safety Briefing

- 12:00-2:00pm Station Rotations

- 2 AIA LU Credits Available

- COST = $15/person includes lunch

PRESENTATION DESCRIPTION:

Live demonstrations where attendees will gain a deeper understanding of spray‑applied enclosure materials, their strengths and limitations, and receive building‑science guidance to select effective, high‑performance systems for specific conditions.

Event: Tuesday August 26th, 2025

MCM Panel Manufacturing Tour & AIA MCM Presentation –

AIA Presentation: Facade Fundamentals - MCM Panels in Practice

Details

DATE: Tuesday, August 26th, 2025

LOCATION: Citadel Architectural Products – Manufacturing Facility

Click Address for Directions 6198 W. Airport Blvd. Greenfield, IN 46140

SCHEDULE & EVENT NOTES:

- 11:0011:45am Check-in, Networking & Box Lunch by Indy Anna’s Catering

- 11:45-12:00pm Introduction by Facility Host

- 12:00-12:15pm BEC IN Opening Remarks

- 12:15-1:00pm AIA Presentation

- 1:00-1:30pm Facility Tour Station # 1 of 3 (Tips & Tricks for Successful Install)

- 1:30-2:00pm Facility Tour Station # 2 of 3 (MCM Factory Cutting)

- 2:00-2:30pm Facility Tour Station # 3 of 3 (MCM Factory Lamination)

- 2 AIA LU Credits Available

- COST = $20/person includes lunch

PRESENTATION DESCRIPTION:

Participants will be able to observe the actual manufacturing process of MCM Panels. In addition, there will be a presentation about various exterior cladding types, key considerations for material selection, and critical performance characteristics such as fire resistance, weather resistance, and environmental durability. Finally, a demonstration area will highlight proper installation techniques, emphasizing their role in moisture management, thermal performance, and compliance with industry codes and standards.

LEARNING OBJECTIVES:

- Describe the manufacturing process of Metal Composite Material (MCM) panels and how quality control during production impacts building performance and durability.

- Identify various types of exterior cladding systems and evaluate their appropriate uses based on environmental exposure, code compliance, and material performance.

- Analyze color, finish, and technical specifications of MCM panels to support design intent while maintaining fire resistance, moisture protection, and long-term safety.

- Demonstrate proper installation techniques for MCM panels that contribute to structural integrity, weatherproofing, and occupant protection.

SPEAKER BIO:

Sean Walker is a Product Manager with 30 years of experience in the construction industry. He specializes in the development, management, and marketing of composite cladding solutions, including metal composite material (MCM). From manufacturing to customer experience, he seeks to utilize a hands-on approach to understand the various phases of the architectural process. Leveraging exposure to a number of different disciplines, his goal is to improve existing products and help find a path for the next iteration of cladding concepts.

Event: Tuesday June 24th, 2025

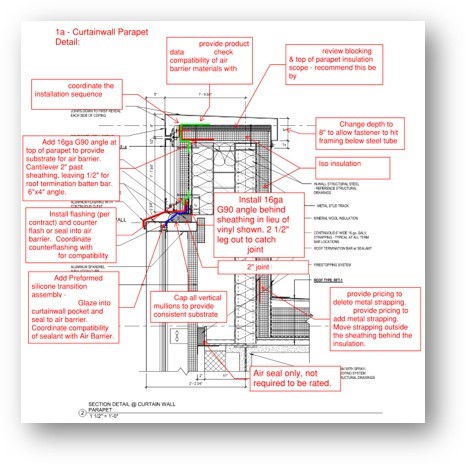

Managing Project-Specific Details for the Building Enclosure –

Real-time Collaboration Between the Design Professional & Product Specialists

Details

DATE: Tuesday, June 24th, 2025

LOCATION: American Structurepoint – Grandview Conference Center

Click address for Driving Directions 9025 River Road Indianapolis, IN 46240

SCHEDULE & EVENT NOTES:

- 8:00-8:30am Check-in, Networking & Breakfast

- 8:30-8:45am Welcome Announcements

- 9:00-10:00am Presentation

- 1 AIA LU Credit

- COST = $15/person

PRESENTATION DESCRIPTION:

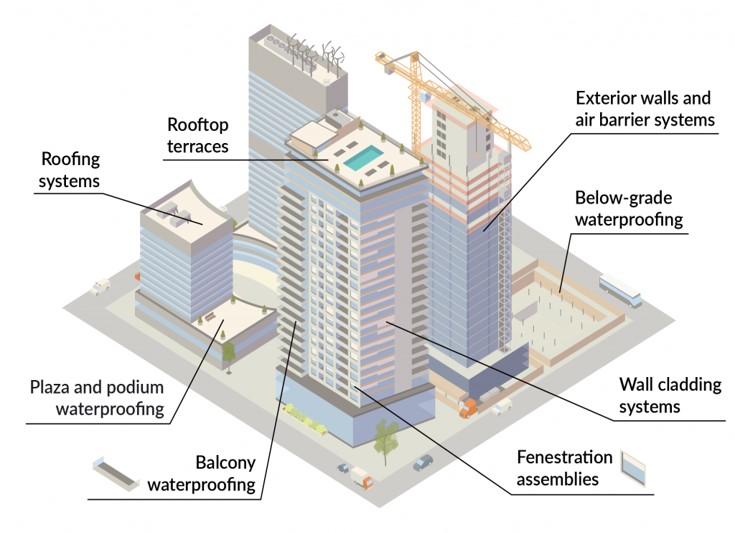

The building enclosure, as the barrier separating interior and exterior environments, requires robust detailing to manage challenges like moisture, air infiltration, and thermal performance. The use of fluid-applied flashing products, for instance, ensures seamless and adaptable protection in complex or irregular areas, which is critical for maintaining the enclosure’s integrity. Additionally, the collaboration between designers and manufacturers strengthens the effectiveness of these solutions, providing tailored approaches to meet specific building enclosure demands. This ultimately supports the overall durability and efficiency of the structure.

LEARNING OBJECTIVES:

- Explain how architectural drawings are sometimes lacking in structure amenable to waterproofing and air-barrier leakage.

- Demonstrate how simple modifications can greatly enhance constrcutability and detailing to prevent water intrusion and air leakage.

- Show how to draw air / water barrier details to facilitate use of fluid-applied products rather than self-adhered membranes and building wrap.

- Explain how to work with manufacturers to optimize preparation of details for implementation by contractors.

SPEAKER BIO:

Chris Tobias is a Building Envelope Technical Specialist with 28 years of experience in construction. He specializes in roofing, air/moisture barriers, and building envelope systems, providing expert consulting, specification development, and architectural detailing support. A leader in the field, he actively contributes to ASTM D-08, IIBEC, BEC, and ABAA committees, shaping industry standards and best practices. His hands-on expertise spans commercial, institutional, and historical restoration projects, ensuring high-performance building solutions.

Event: Wednesday April 23rd, 2025

Building Science in Action – Interactive Stations at the Indiana Archives Project

Details

DATE: Wednesday, April 23rd, 2025

LOCATION: 350 West Ohio St Indianapolis, IN 46204

SCHEDULE & EVENT NOTES:

- 10:30-11:00am Registration and networking

- 11:00-11:45am Welcome & Introductions

- *11:00am – Lunch at IN Historical Society Terrace Cafe

- Provided by Jonathan Byrd’s Catering

- 11:45-12:30pm Project Info & Safety Briefing

- 12:30-2:30pm Project Site Station Rotations

- **Bring PPE: Hard Hat, Safety Glasses, Closed-Toe Shoes

- Earn 2 AIA LU Credits

EVENT BRIEF:

Attendees will be given access to this unique project site via 3 learning stations that combine state-of-the-art enclosure design with challenging construction logistics. Hear an owners perspective from Jason Larrison of J.S. Held. Ratio Architects will introduce the scope of the project, and Pepper Construction will provide an overview of the BIM-based enclosure coordination.

Station Descriptions

Station 1: Magnesium Oxide Structural Insulated Sheathing

Representatives from Interior Supply, Circle B, Dupont, and Tremco will explain the benefits and challenges of the magnesium oxide structural insulated sheathing panels. The panels have a pre-applied air barrier and a 2-hour fire rating. Exterior cladding systems are directly attached to the outside face of the panel using tested fasteners. For this project, the rough openings were wrapped with a peel-and-stick membrane for AVB continuity.

Station 2: PreGlazed Curtainwall Assemblies

Blake Pond and Nate Linder of Hall Aluminum will explain the benefits and challenges of their innovative approach to preglaze the curtainwall assemblies in their Fort Wayne shop, then ship them to Indy and install them from the interior. This approach requires additional coordination but allows for shop assembly, saving time in the field and resulting in a higher-quality installation. Blake and Nate will also explain how the panels are rigged, lifted, and set from inside the building.

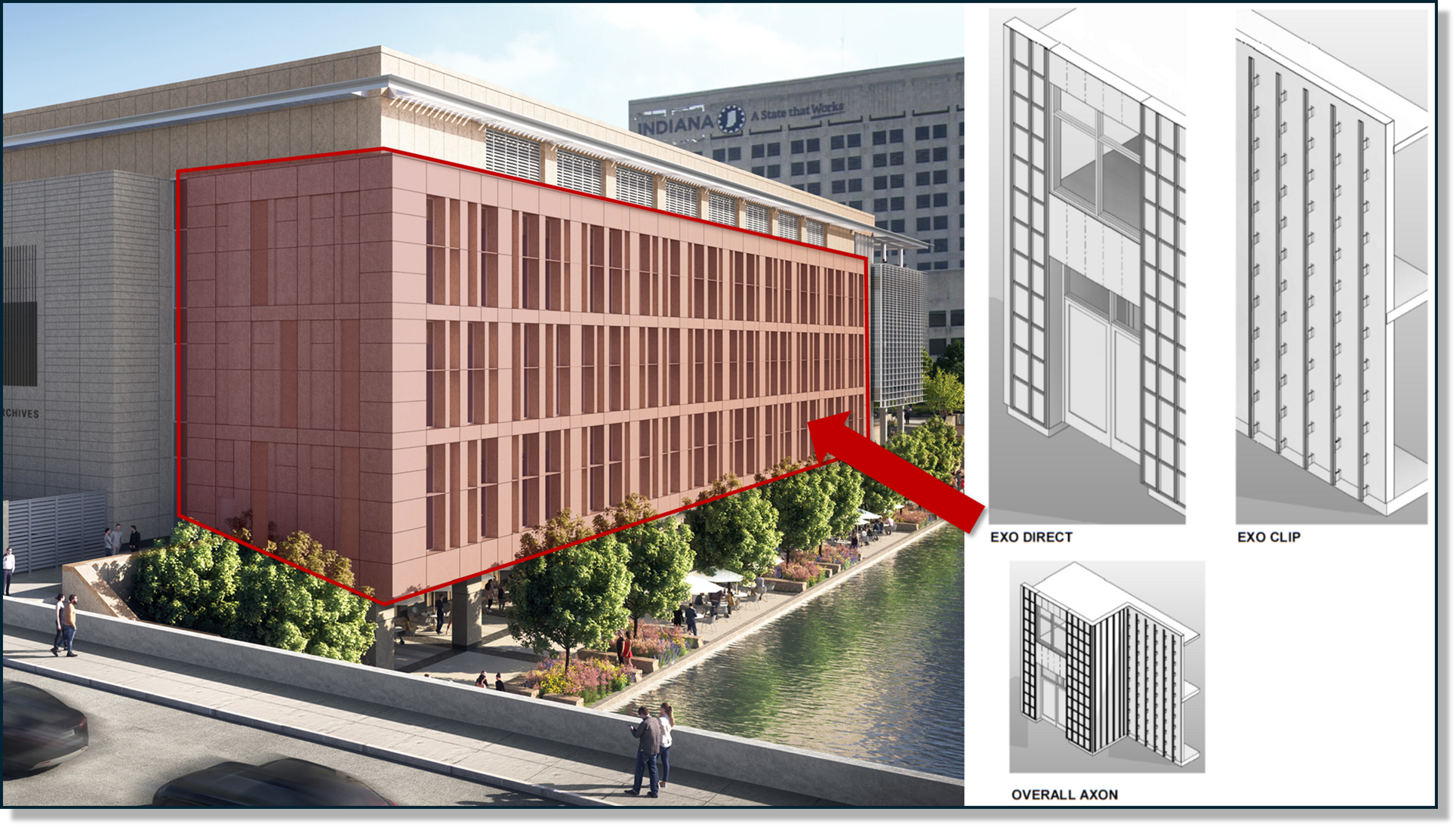

Station 3: Rainscreen Attachment System & Exterior Panels

Jim Yeary Ram North America and Sierra Yeary of Exo Systems will explain their rain screen attachment system, which was invented and produced in Indiana. They will help participants consider the critical features of a rain screen attachment system and some of the design considerations during development. Ram North America and installing contractor, Mohawk Construction will review the exterior panels for this project and how they are integrated into the central screen attachment system.

Event: Wednesday Feb 19th, 2025

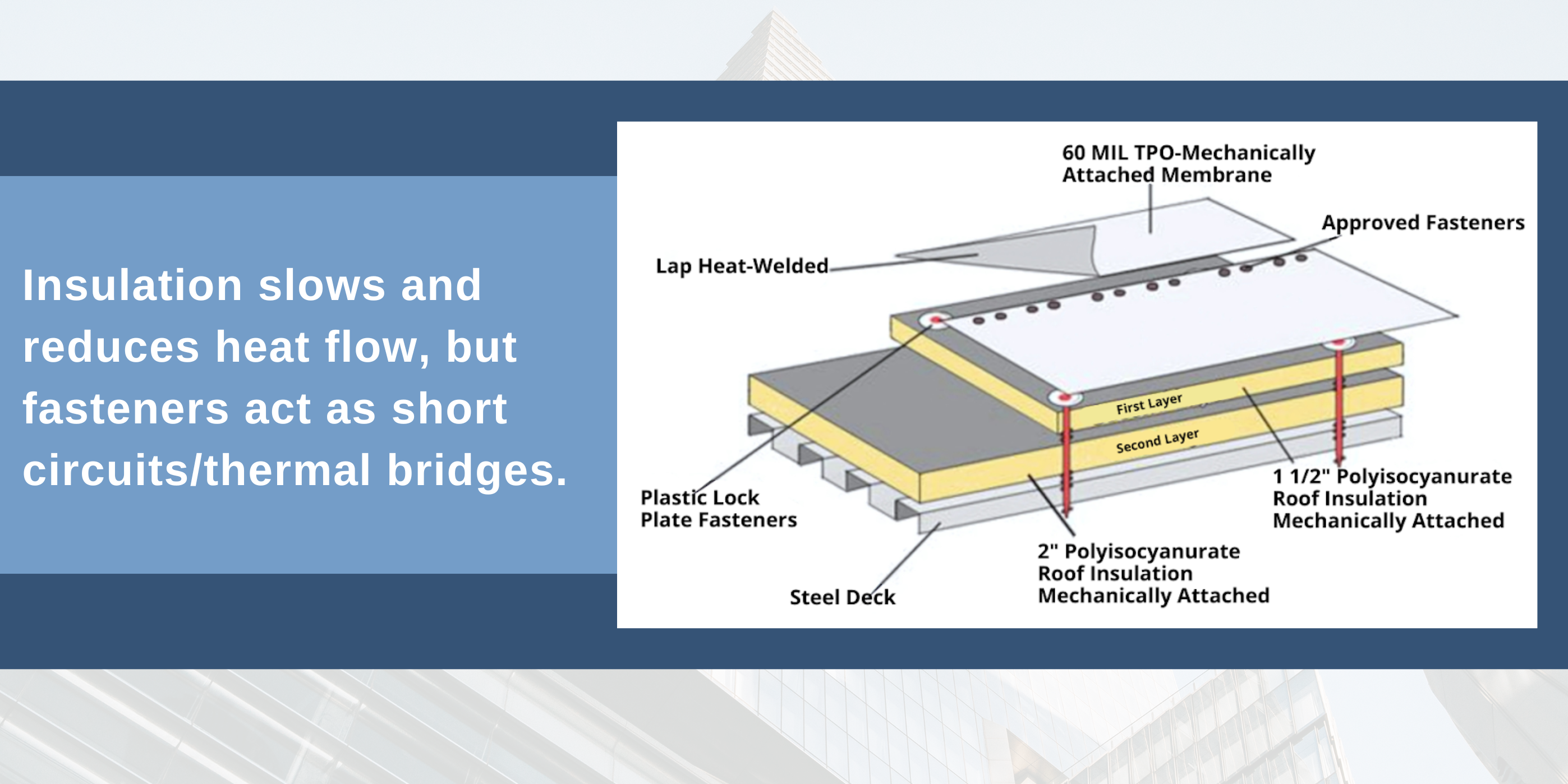

Roofing for the Future: Cost-Benefit Insights on Thermal Bridging & R-Value Optimization

Details

Wednesday, February 19, 2025 10:00am American Structurepoint, 9025 River Rd, 3rd Floor Conference Room, Indianapolis, IN 46240

Schedule:

- 8:00-8:30am Registration and networking

- 8:30-10:00am Presentation

- Breakfast will be provided

Credit: 1 AIA Credits Available

This session will explore the potential impact of fastening patterns on the thermal performance of roofing systems. Specifically, we will examine how variations in R-value between the “as-designed” and “as-constructed” conditions can lead to economic costs. Furthermore, we will analyze the total system costs associated with different roofing assemblies and investigate how attachment methods influence long-term performance benefits and energy savings.

Learning Objectives

- Understand possible reduction in R-value due to fastening pattern.

- Economic cost associated with reduced R-value from as designed to as constructed.

- Total system costs for different roofing assemblies.

- How attachment methods affect long term performance benefits & energy savings

Event: Thursday Nov 21st, 2024

Vapor Unfiltered: Should My Air Barrier be Vapor Permeable or Not?

As energy codes become more stringent, architects are becoming increasingly more familiar with the concept of controlling air leakage across building enclosures. Architects are less familiar with the code requirements for water vapor permeance in building materials and why these requirements are important in enclosure design. During this session, industry experts will break down how and why vapor permeance should be considered and factors that could influence the desired vapor permeability properties of air barrier systems.

Learning Objectives

- Participants will be able to use correct terminology, analyze material properties for air permeance and water vapor permeance, and recognize why it is important to consider both in selecting enclosure materials.

- Participants will be able to recognize potential health risks associated with improper design of building enclosures with regards to vapor permeability.

- Participants will learn about design factors, building typologies, and construction types that affect the selection of air barrier materials and their vapor permeance characteristics.

- Participants will learn code requirements for vapor permeability and best practices for determining vapor permeability properties of air barrier systems, which are not necessarily always aligned.

Event: Tuesday Oct 22nd, 2024

Building Envelope Commissioning and Testing Basics

**Please note, there is a new location for this event!

This session will provide a deep dive into the field of Building Enclosure Commissioning. Attendees will gain a clear understanding of the definition of Building Enclosure Commissioning, explore relevant standards and guidelines, and delve into the comprehensive Building Enclosure Commissioning process. We will also discuss common performance testing methods associated with Building Enclosure Commissioning and provide an overview of the qualifications and certifications required for Building Enclosure Commissioning professionals.

Learning Objectives

- Define building enclosure commissioning

- Explore current BEC standards and guides

- Discuss the overall BEC process

- Identify performance testing typically included with BEC

- List BEC qualifications and certifications

Details

- Tuesday October 22, 2024

- American StructurePoint Grandview Conference Room, 3rd Floor – 6025 River Road Indianapolis, IN 46240

- 8:00 am – 8:30 am | Registration and Networking

8:30 am – 10:00 am | Presentation - $15.00, includes Breakfast

- Credit: 1 AIA CEU

Event: Tuesday June 4th, 2024

Building Envelope Success: Preventing Air Barrier Failures

Air Barriers are a newer technology in our building industry. Prior to 2001, there were no codes, or US standards referring to air barriers. However, Building Science and physics have proven air barriers to be one of the most important aspects of the building enclosure for durability, longevity, and moisture management.

This presentation, led by Mr. Stroik, the former Chair for the Air Barrier Association of America (ABAA), a Certified Air Barrier Specialist (CABS), and a voting member of ASTM E06-Building Performance, will touch on design/specification things to consider and avoid, along with a discussion on the actual field installations of air barriers, looking at the good and perhaps some installations that might need a little help.

Learning Objectives

- Understanding air barriers are important for our buildings to properly function

- Understanding proper detailing of air barriers to ensure they properly function

- Reviewing important pre-installation steps to ensure the right air barrier is going to be applied to your project

- Using actual Field examples to understand the good, the bad, and the ugly of air barrier installations

Details

- Date: Tuesday June 4th, 2024

- Location: Guggman Haus Brewing Co. (Festhall Event Space)

- Check-in: 4:00

- Beer & Appetizers: 4:00-5:00pm

- Presentation: 5:00-6:00pm

During this time, he focused on Quality processes and LEAN Construction, along with developing and implementing various standard operating procedures based upon the scientific method of Plan, Do, Check, Adjust. He currently works for American Contractors Insurance Group (ACIG), where he assists in developing and deploying quality processes and performance excellence to US privately owned Construction Managers.

Brian is the past chair and a Fellow of the Air Barrier Association of America (ABAA), the past chair of the National Building Enclosure Council (NBEC), a Certified Air Barrier Specialist (CABS), a past chair of the Wisconsin Building Enclosure Council, is on the Board of Directors for the Building Enclosure Technology and Environmental Council (BETEC), a Senior Member of the American Society of Quality (ASQ), and a voting member of ASTM E06 – Building Performance.

Event: Thursday April 11th, 2024

A New Era of Construction: Innovations & Insights in Insulated Metal Panel Integration in the Building Enclosure.

Integrating IMP (Insulated Metal Panels) into the building enclosure involves several key steps to ensure that the building is not only energy efficient but also structurally sound and aesthetically pleasing. Come learn about what is required to plan and coordinate the various construction trade disciplines and discuss the importance of detailing to ensure successful integration into the building enclosure.

Learning Objectives

- Facility Tour of How IMP Panels are made.

- Discussion on Critical Details Needed on Project Drawings.

- Steps Provided to Help Bid the Project Competitively and Avoid Errors in the Field.

- Industry Update on things to know regarding Insulated Metal Panels

Details

- Date: APRIL 11th, 2024

- Location: NUCOR Metl-Span Facility: 1717 McCall Dr, Shelbyville, IN 46176

Carl Veith is an experienced Designer with a demonstrated history of working in the architecture & planning industry. Skilled in AutoCAD, Computer Aided Design (CAD), Communication, and Revit. Strong arts and design professional with a Master of Architecture (MArch) focused on Architecture from Kent State University. 11 Years of architectural design with 6 years of advance food manufacturing design. Carl has been with Nucor Insulated Panel Group for the past 3 years.

Stephen graduated from Purdue University with a degree in Civil Engineering. Upon graduation, he designed steel stud curtain wall systems for the country’s largest steel framing manufacturer. He then went on to work for a large mid-western based restaurant chain managing the design and development of new restaurants in the eastern half of the country. Stephen joined Engineered Facades in 2009.

Event: Thursday Dec 7th, 2023

END OF YEAR SOCIAL EVENT: GO FOWLING WITH BEC

Join us for a fun afternoon of throwing footballs at bowling pins, enjoying BBQ with all the trimmings, cheering a tasty beverage and meeting great people within our industry. No experience required, but having an arm like Uncle Rico is a plus.

Details

- Date: Thursday December 7th

- Location: The Fowling Warehouse Indianapolis – 1125 East Brookside Ave Indianapolis, IN 46202

Event: Wednesday Nov 1st, 2023

JOBSITE VISIT: St. Vincent Women’s & Children’s Hospital

Details

- Date: Wednesday November 1st

- Location: St Vincent Women’s & Children Hospital – 2001 W. 86th Street Indianapolis, IN 46240

Event: Wednesday Aug 23rd, 2023

BEC of IN SUMMER PRESENTATION

Stormwater Retention Roofs: What Roofs Use Stormwater Management, How to Design Them, and the Effectiveness in Urban & Dense Environments. While retention roofs are not a new practice, you need only history to tell stormwater utilities’ evolution and sewer systems’ evolution.

Certainly, influences of modifications in stormwater codes/ordinances, driven by the EPA/Clean Water Act, impact the “NEW” stormwater codes/ordinances. You need the entire team of Utilities, Designers, Engineers, and Manufacturing partner for best practice at a competitive cost.

Learning Objectives

- Learn what roofs use stormwater management and how to design them.

- Discuss membrane types, installation differences and leak detection.

- Hear about the effectiveness and cost of stormwater management options for urban and dense environments.

Details

- Date: Wednesday August 23rd

- Location: River Road Conference Center – 9045 River Road Indianapolis, IN 46240

Event: Tuesday Feb 13th, 2023

Fenestrations in the Building Envelope… What Could Go Wrong?

Detailing successful integration of openings for a successful Building Enclosure – We can’t become an expert on fenestration systems and rough opening waterproofing in 45 minutes, but we can gain exposure to many different considerations and issues to be aware of. This presentation will provide definitions, basics, photos, diagrams, and a video of real construction issues observed and remediated.

Learning Objectives

- Important definitions of fenestration systems from AAMA/WDMA/CSA 101/I.S.2/A440-17

- Basics of common fenestration systems and waterproofing

- The importance of testing

- Considerations and issues to look out for in construction

Details

- Date: Tuesday February 13th

- Location: River Road Conference Center – 9045 River Road Indianapolis, IN 46240